Upgrade your team’s toolset.

Don’t waste time looking up work history or communicating back and forth over email. Provide all the information your team needs, even on the go.

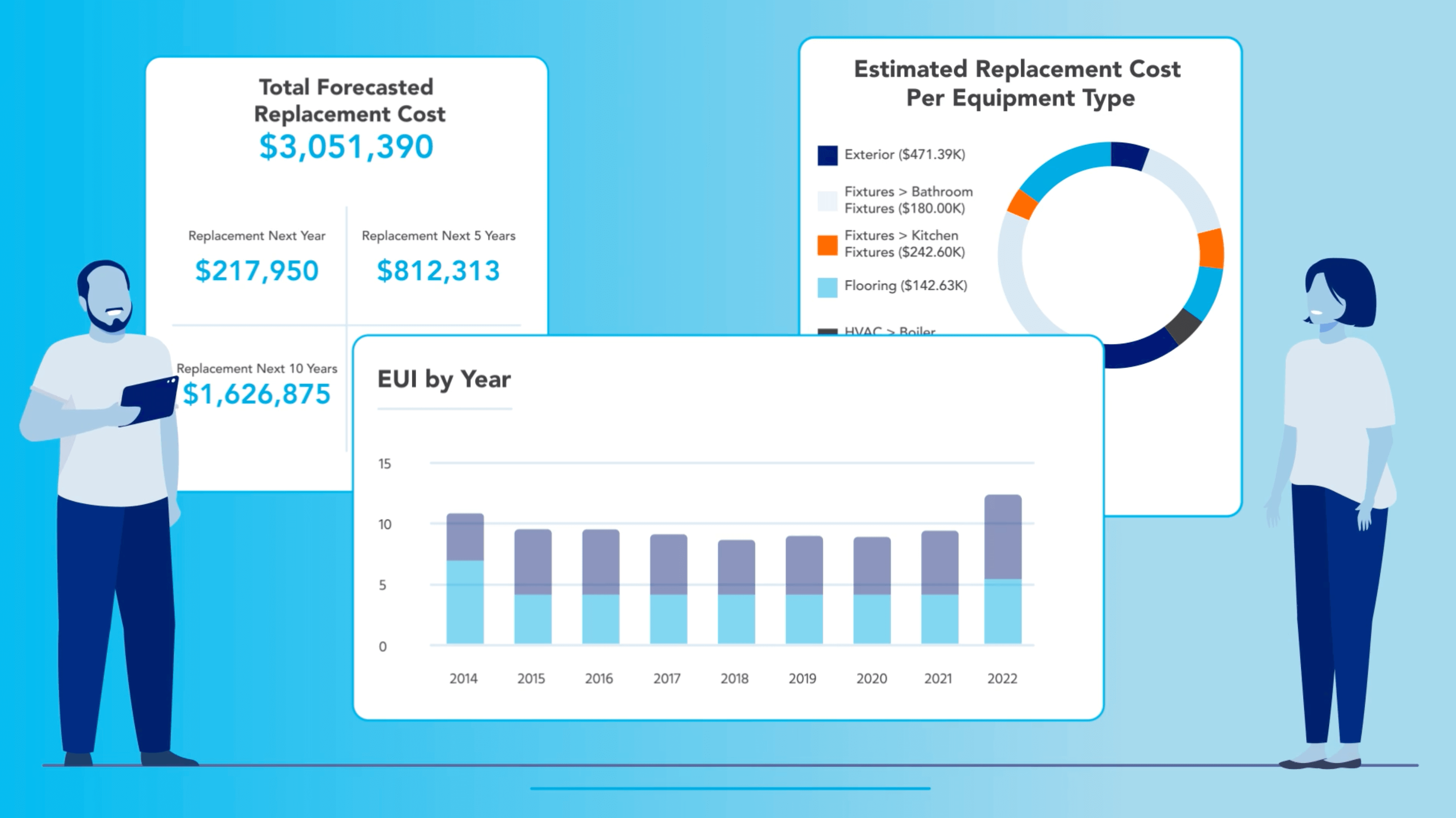

Stop the leaks in your operating budget.

It’s hard to see where time and money are wasted—and even harder to fix it. Organize your performance data to effortlessly uncover areas for improvement.

Streamline scattered processes.

Work takes longer when you’re juggling countless conversations and disconnected processes. Coordinate with other teams to keep things running and never miss a beat.

A better way

Take control of your operations with innovative, easy-to-use software.

- Put your day-to-day management on autopilot

- Say goodbye to emails, phone calls, and paper forms

- Execute data-informed decisions and planning

Industries we serve

Organizations of all sizes use FMX to optimize their facilities and maintenance processes.

Built with your needs in mind

Proudly serving over 400K professionals like you

The transition from our other system to FMX could not have been smoother and easier. The team at FMX are experts in the needs of school districts like ours.

$700k projected annual savings

Automates HVAC and lighting schedules to match building usage and reduce utility costs.

One thing I don’t have to think about as we grow is whether or not the database can support our growth. All it takes is an email [to support] to set up a new store. I wouldn’t want to work with anybody else.

2 hours to set up a new restaurant in FMX

Easily scales maintenance processes with restaurant location expansions.

All CMMS systems are going to have similar functionality. But FMX is by far the easiest to use, and their amazing customer support sets them above the rest.

20 hours saved per week for the facilities manager

Regained time wasted delegating work with an automated routing system.

97% reduction in invoice creation time

Automatically fills in invoice details to eliminate time wasted manually creating them.

There was no doubt that FMX was exactly what we needed. More staff are submitting work orders than we’ve ever had with any other system, and that is because FMX is so easy to use.

90% decrease in work order resolution time

Gained better organization and visibility to resolve requests more efficiently.

We needed a solution that was a good balance between a maintenance database and facilities calendaring software. FMX proved to hit the sweet spot for us.

75% more efficient when scheduling events

Regained time spent manually logging and updating event details

It’s not a "this is what it is—you just figure out how to work with the system" kind of software. FMX is making updates and constant improvements.

75% decrease in staff complaints

Keeps staff up to date on the status of work orders in real time.

FMX always puts the customer first. They work with the customer on what their desires are, and never try to shove them in a cookie-cutter box. They actually care about how I want to do business.

31% decrease in work order resolution time

Now teams resolve work faster through better organization and communication.

We chose FMX for our new plant because it offered our staff the ability to work anytime, anywhere, on any device with an ease-of-use that others couldn’t match.

$18K annual inventory savings

Improved inventory control and preventive maintenance initiatives.

FMX gives me capabilities I never had before. Now I can look at the equipment in each of our restaurants and verify the frequency and cost of every repair.

$33K equipment cost savings in the first 3 months

Identified areas in need of improvement—and learned when it was cost-effective to replace equipment.

FMX brought it all together for us, helping us continuously manage our facilities, maintenance, scheduling, transportation, technology, and building automation processes. Now I can focus on what’s most important—our students.

80% reduction in ticket volume

Reduced overall incoming tickets through one organization-wide system.

FMX stood above nearly a dozen other facilities and maintenance management solutions. Their ease-of-use, application performance, and customer service were superior in every way.

$450K annual productivity savings

Eliminated time spent organizing, prioritizing, and dispatching work.

Don’t take our word for it

FMX is recognized as one of the most-reviewed and highest-rated CMMS providers based on usability and customer satisfaction.

400+ reviews on Capterra, Software Advice, and GetApp

Featured resources, picked for you

Award

2024 Technician of the Year Award

Honor our unsung heroes in facilities management by nominating a technician, mechanic, groundskeeper, electrician, plumber, specialist, custodian, or other skilled facilities specialist.

Built for K-12

We Believe Students Come First

Our goal is to meet your district where it’s at and provide an easy-to-use solution that helps you best serve your school.

Assessment

Free K-12 Preventive Maintenance Assessment

Take our quick preventive maintenance assessment to evaluate your district's preventive maintenance performance and ways to track your success.

Course

Free Preventive Maintenance Course

3 lessons from maintenance leaders about moving from a reactive to a proactive strategy. Get instant access to the first lesson.

Podcast

Introducing Beyond Buildings, a new podcast powered by FMX

Join Brian Gregory as he speaks with facilities leaders across the country about triumphs and challenges.

Assessment

Take the Preventive Maintenance Assessment

Get instant feedback on your organization's PM execution—and an action plan for improvement.

Assessment

5 Property Maintenance Checklists

Checklists are a simple but incredibly effective tool that can ensure quality maintenance inspections from your team time and again with almost no financial investment.

eGuide

11 Reasons Why FMX Is Your School's Ideal FM Solution

FMX is a one-stop-shop for all of your school's needs. Find out why.

eGuide

5 Differentiators that Make FMX Your Ultimate CMMS Solution

FMX helps thousands of organizations achieve their maintenance goals. Find out why.

Case Study

Grand Prairie ISD

Grand Prairie Independent School District takes control of maintenance & operations with FMX

Case Study

Ultradent Manufacturing

Large manufacturing company uses FMX to implement a preventive maintenance plan.

Case Study

Brumit Restaurant Group

Large Arby’s franchise uses FMX to manage their growing business.

Case Study

Faith Baptist Church

Church leverages FMX to meet major objectives: easy tracking of maintenance issues and efficient event management.

Case Study

Polynesian Cultural Center

Polynesian-themed cultural museum uses FMX to deliver new levels of operational excellence.

Product Features

FMX add-ons and integrations

Extend FMX with powerful add-ons to optimize your facilities and maintenance operations.

Free Download

Customizable Work Order Template

Give your team the foundation it needs to successfully prioritize and execute every maintenance task. Get it in place for your team today.

Assessment

6-Point Facilities Management Performance Inspection

Get feedback on the health of your facility’s operations by taking this short diagnostic survey.

Checklist

14 Must-Have Facilities Management Checklists

A facilities management checklist can help your equipment live longer and reduce reactive maintenance repairs for your team. See what to add to your list.

![[Hidden] FMX Tour - Reports](https://www.gofmx.com/wp-content/uploads/2023/07/fmx-reporting-tour-thumb.png)